This lab is utilized by all students and faculty of Chemical Engineering for all wet chemical experiments. The Technical Analysis Laboratory is especially dedicated for the 2nd Year Chemical Engineering Students practical classes. Previously it was known as Chemical Analysis Lab.

A U-tube manometer with controller of first order and second order is an apparatus used to measure pressure in a variety of applications. It consists of two U-tubes connected at the bottom and a controller connected to the top of the tubes. The controller is used to adjust the pressure in the tubes. The first order controller is a single-parameter device that adjusts the pressure in the tubes based on a single input, such as a set point. The second order controller is a multi-parameter device that adjusts the pressure in the tubes based on multiple inputs, such as temperature, humidity, and pressure. This allows for more precise control of the pressure in the tubes. The U-tube manometer with controller of first order and second order is used in a variety of applications, such as water treatment, HVAC, and industrial process control.

A non-interacting and interacting system apparatus is a type of laboratory apparatus used to study systems that interact with each other. The non-interacting system consists of two subsystems that are not connected to each other in any way. The interacting system consists of two subsystems that can interact with each other. This apparatus can be used to study a variety of different systems, such as mechanical, electrical, and chemical systems. The apparatus can also be used to study the effects of control systems on systems, such as feedback control and feedforward control. By studying the systems, researchers can gain insights into how the systems interact and how to control them.

A characteristic of different types of control valve apparatus is an instrument used to measure the performance of a variety of control valves. It is used to measure the flow rate of a fluid, the pressure drops, the opening and closing times, the stability, and the noise generated by the valve. The apparatus can be used to test a variety of valves, such as globe valves, butterfly valves, and diaphragm valves. By testing the valves, engineers can determine the best type of valve for a particular application. The apparatus also allows engineers to optimize the design of the valve, ensuring that it performs as expected.

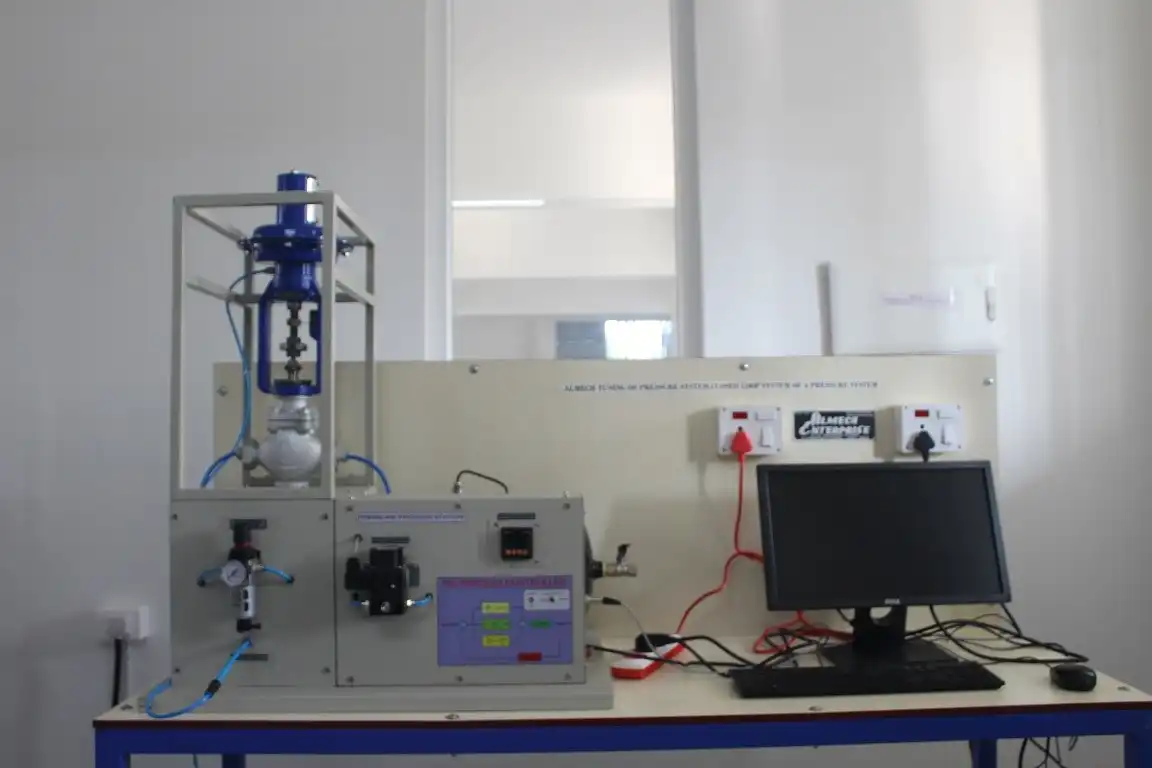

A tuning of pressure system: closed loop system of pressure system is a type of laboratory equipment used to study and optimize the operation of pressure systems. The system consists of three main components: the pressure system, the controller, and the feedback loop. The pressure system is a set of valves and sensors that measure and regulate the pressure in the system. The controller is a device that adjusts the pressure system based on the feedback from the sensors. The feedback loop is a system of sensors and actuators that measure the performance of the pressure system and send the information back to the controller. By studying the system, engineers can optimize the operation of the pressure system for different conditions and situations.

A flow transmitter closed loop study of a closed system apparatus is a type of laboratory equipment used to study and optimize the operation of flow transmitters. The apparatus consists of a flow transmitter, a controller, and a feedback loop. The flow transmitter is a device that measures the flow rate of a fluid. The controller is a device that adjusts the flow rate of the fluid based on the feedback from the sensors. The feedback loop is a system of sensors and actuators that measure the performance of the flow transmitter and send the information back to the controller. By studying the system, engineers can optimize the operation of the flow transmitter for different conditions and situations.

.webp)

A cascade control trainer (level and flow apparatus) is a type of laboratory equipment used to study and optimize the operation of cascade control systems. The apparatus consists of two subsystems: a level system and a flow system. The level system consists of a tank and sensors that measure the liquid level in the tank. The flow system consists of a pump and sensors that measure the flow rate of the liquid. The cascade control system is a system of controllers and actuators that adjust the level and flow of the liquid based on the feedback from the sensors. By studying the system, engineers can optimize the operation of the cascade control system for different conditions and situations.

An open loop study - closed loop study thermal system, temperature loop system apparatus is a type of laboratory equipment used to study and optimize the operation of thermal systems. The apparatus consists of a thermal system, a controller, and a feedback loop. The thermal system is a set of heat exchangers and sensors that measure the temperature of the system. The controller is a device that adjusts the thermal system based on the feedback from the sensors. The feedback loop is a system of sensors and actuators that measure the performance of the thermal system and send the information back to the controller. By studying the system, engineers can optimize the operation of the thermal system for different conditions and situations.

A level transmitter closed loop study tuning of level system apparatus is a type of laboratory equipment used to study and optimize the operation of level systems. The apparatus consists of a level system, a controller, and a feedback loop. The level system is a set of tanks and sensors that measure the liquid level in the tanks. The controller is a device that adjusts the level system based on the feedback from the sensors. The feedback loop is a system of sensors and actuators that measure the performance of the level system and send the information back to the controller. By studying the system, engineers can optimize the operation of the level system for different conditions and situations.