Air and water, both of which are fluids, surround our entire life. Hence understanding fluid behavior is vital for a Chemical Engineer to operate in and on these fluids. Thus, it is important that students gain proper understanding and demonstrate practical skills in fluid mechanics. We have 14 equipment covering closed flow, open flow, various flow meters, various pumps and determination of fluid viscosity.

This setup is used to determine density and viscosity of unknown fluids using a specific gravity bottle and terminal velocity of a solid ball falling through the unknown fluid.

Redwood viscometer is used to determine the viscosity of unknown fluid by estimating the time to collect 60 mL of fluid falling through an orifice

Reciprocating pump setup is used to determine the characteristic performance curve of a reciprocating pump by determining the power required to pump water at various flow rates

Centrifugal pump test rig is used to determine the characteristic performance curve of a centrifugal pump by varying the flow rate and determining the power required to pump

Notch weir test rig is used to determine the flow rate of water over flowing a dam like setup. This flow rate varies with the fluid height above the notch

Open drum with orifice test rig is used to estimate the time required to drain a tank containing fluid until a particular height

Fluidized bed column setup can be used to determine the pressure drop created at various flow rates and bed porosity.

Packed bed column setup is used to determine the pressure drop created by the packing ceramic beads packed fully in the column.

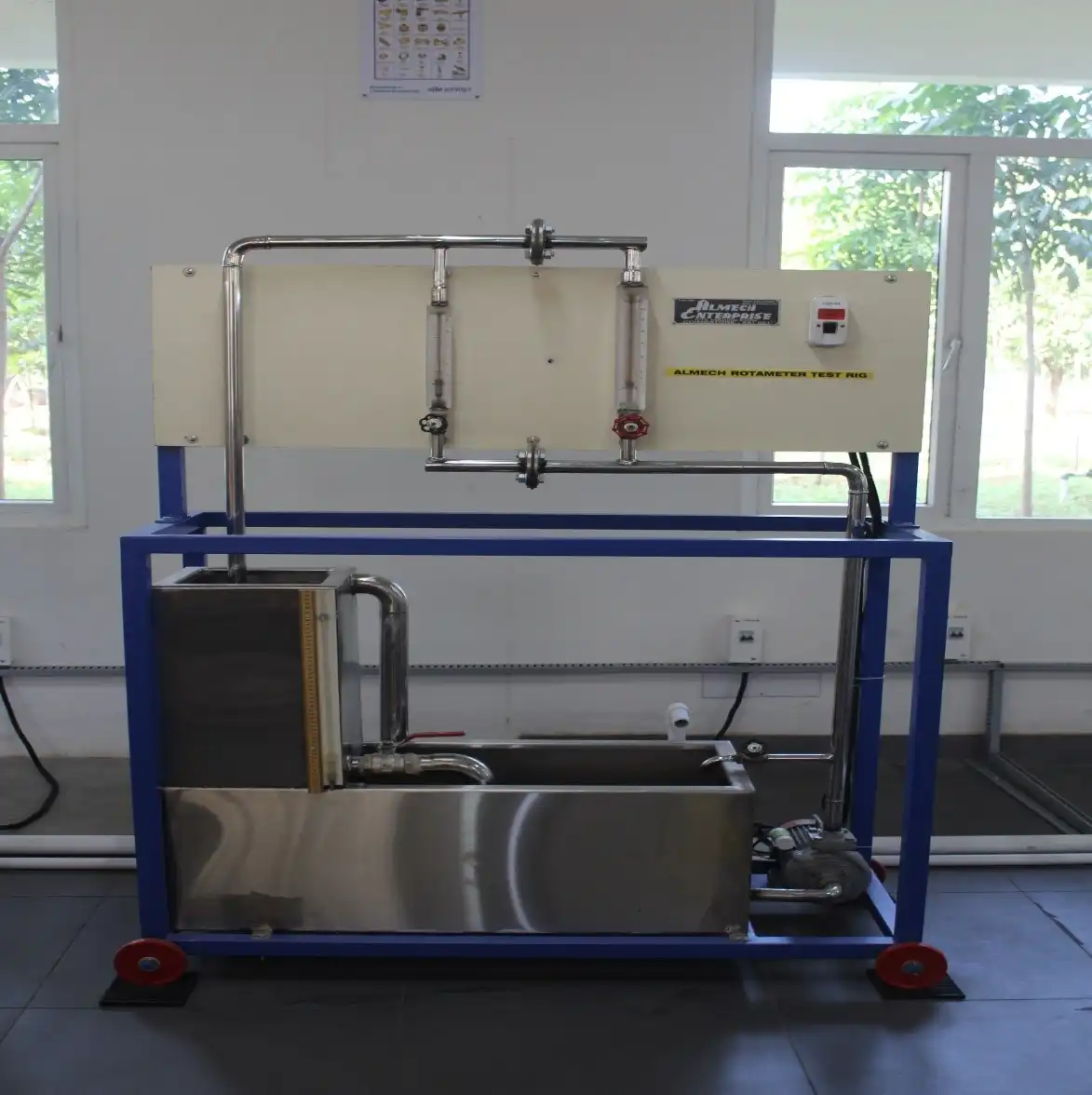

Rotameter is directly used to know the flow rate of a fluid based on the balance of buoyancy, weight and drag force of a solid float present inside the meter. It is used for knowing flow rate of transparent fluid.

Helical and spiral columns are used for passive mixing of multiple fluids due to Coriolis force. In this setup, the pressure drop generated by helical and spiral column of same length and diameter is compared using an U-tube manometer connected to them

Venturi meter is used to determine the flow rate by creating a pressure drop using cone shaped contraction and expansion sections. These contraction and expansion sections allow flow rate measurement by minimum pressure drop.

Pressure drop in long pipe, rough bend, smooth bend, sudden expansion and sudden contraction can be determined at various flow rates to find the loss coefficient K of each fitting.

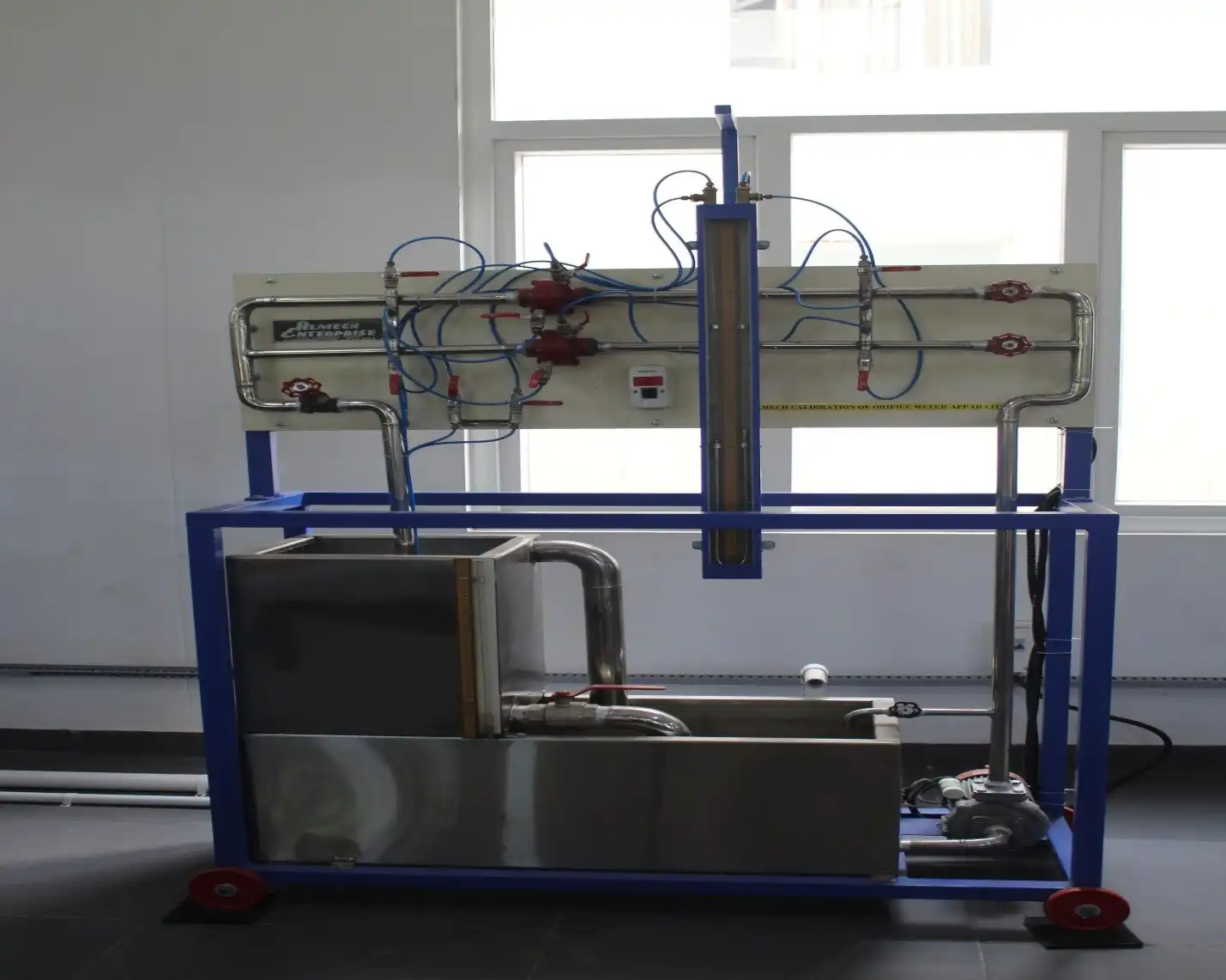

Orifice meter is used to determine the flow rate by creating a pressure drop using a circular disc that has a hole (orifice) at the centre. The pressure drop here is high as there is no arrangement to recover the lost pressure. However orifice meter range i.e minimum and maximum measurable flow rate can be easily changed by changing the hole diameter

The gear pump setup is used to study the characteristic performance curve of the gear pump at various flow rate values.