Mass Transfer Laboratory is one of the most significant labs in terms of Chemical Engineering. The operations of mass transfer Laboratory studies separations and mass transfer experimentally. The laboratory experiments are designed in such a way that they can cover basic stage-wise separation operations like distillation in packed columns, absorption in packed columns, extraction, and leaching as well as basic fundamental mass transfer like diffusion through gas, diffusion through liquid, humidification, etc. It introduces experimental design, correlation, and data interpretation. Mass transfer studies are conducted in laboratory settings to gain a better understanding of these processes, and the results of these studies help researchers design new materials, processes, and systems. Mass transfer studies can be used to develop improved separations, reactors, and other advanced systems that can be used for advanced chemical engineering applications

Simple distillation apparatus is often used to study the physical phenomena of vaporization and condensation. It involves heating a liquid at a constant temperature to evaporate its components and then recapturing the resulting vapor by cooling. The resulting vapor can be collected and analyzed to gain a better understanding of the distillation process. This type of apparatus is commonly used to separate and purify different chemical compounds and is an important process for chemical engineers. Separation and purification of chemicals can be carried out using the distillation.

Steam distillation involves distilling water along with other volatile and non-volatile ingredients. The volatile leftovers are carried by the steam from the boiling water to a condenser, where they are cooled and transformed back into liquid or solid form, leaving behind the non-volatile residues in the boiling container. The volatiles will spontaneously form a distinct phase after condensation if, as is typically the case, they are not miscible with water. This will allow them to be separated by decantation or with a separatory funnel. Steam distillation can be used when the boiling point of the substance to be extracted is higher than that of water, and the starting material cannot be heated to that temperature because of decomposition or other unwanted reactions. Steam distillation once was a popular laboratory method for purification of organic compounds, but it has been replaced in many such uses by vacuum distillation and supercritical fluid extraction. It is however much simpler and economical than those alternatives, and remains important in certain industrial sectors.

Packed columns are used for distillation, gas absorption and liquid-liquid extraction. The gas-liquid contact in a packed column is continuous, not stage-wise, as in a plate column. The liquid flows down in the column over a packing surface and the vapor (or the gas) moves counter-currently, up the column. The performance of a packed column is very dependent on the maintenance of good liquid and gas distribution through the packed bed, and this is an important consideration in packed column design.

Liquid-liquid extraction is a method to separate compounds or metal complexes, based on their relative solubilities in two different immiscible liquids, usually water (polar) and an organic solvent (non-polar). There is a net transfer of one or more species from one liquid into another liquid phase, generally from aqueous to organic. The solvent that is enriched in solute(s) is called extract. The feed solution that is depleted in solute is called the raffinate. LLE is a basic technique in chemical laboratories, where it is performed using a variety of apparatus, from separatory funnels to countercurrent distribution equipment called as mixer settlers.

Drying is a crucial unit activity to remove moisture in chemical processing sectors like food processing, pharmaceuticals, agriculture, and textiles. Vacuum drying is typically used to dry hygroscopic and heat-sensitive materials. It is based on the idea that by creating a vacuum, the chamber pressure can be reduced below the boiling point of water, which will cause the material to dry. Vacuum pumps are used to lower the pressure surrounding the material to be dried. As a result, the water inside that product has a lower boiling point, which dramatically raises the rate of evaporation. The end effect is a noticeably faster rate of drying for the good. To enable quicker drying, the vacuum drying process is a batch operation carried out at lower pressures and relative humidity compared to ambient pressure.

Tray dryer is a type of industrial equipment used in the mass transfer laboratory to dry, evaporate, and dehydrate materials. It consists of a heating chamber with shelves or trays where wet material is placed. Heat is circulated throughout the chamber, evaporating the moisture from the material as it passes through the chamber. The tray dryer helps mass transfer researchers gain a better understanding of evaporation and dehydration processes, which can be applied to the development of more efficient separations, reactors, and other advanced systems. Tray dryers can also be used to improve the efficiency of certain operations, by introducing a controlled amount of heat or drying time. The results of these studies allow researchers to design new materials, processes, and systems that will improve the efficiency of production processes and reduce the environmental impacts associated with manufacturing. Additionally, tray dryers can be used to control the quality of the end product, ensuring a consistent and reliable product.

Ion exchange is a reversible interchange of one kind of ion present in an insoluble solid with another of like charge present in a solution surrounding the solid with the reaction being used especially for softening or making water demineralised, the purification of chemicals and separation of substances. Ion exchange usually describes a process of purification of aqueous solutions using solid polymeric ion-exchange resin. More precisely, the term encompasses a large variety of processes where ions are exchanged between two electrolytes. Aside from its use to purify drinking water, the technique is widely applied for purification and separation of a variety of industrially and medicinally important chemicals. Although the term usually refers to applications of synthetic (man-made) resins, it can also include many other materials.

Rotating Disc Contactor (RDC) are columns which are used for liquid-liquid extraction process and they are widely used in chemical industries. They are usually used to remove impurities from liquid mixtures. A rotating disc contactor is used in laboratories to study processes involving liquid-liquid systems. The device consists of a horizontal, rotating disc located in the centre of a cylindrical vessel. As the disc rotates, it creates a differential pressure between the two liquids in the vessel, causing them to mix and allowing for efficient mass transfer to take place. The use of this device helps researchers gain a better understanding of the various physical and chemical processes associated with liquid-liquid systems and can be used to develop more efficient separation technologies.

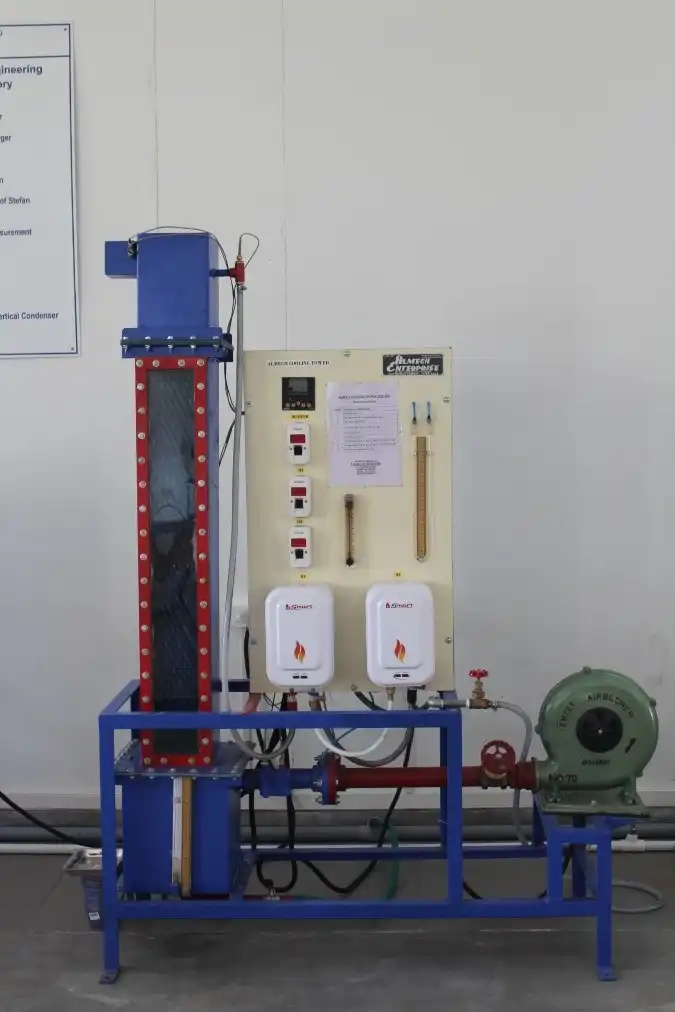

A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature using radiators. Common applications include cooling the circulating water used in oil refineries, petrochemical and other chemical plants, thermal power stations and nuclear power stations. The classification is based on the type of air induction into the tower. The main types of cooling towers are natural draft and induced draft cooling towers

An absorption column apparatus is a type of mass transfer device used in laboratories to study the process of gas absorption. The apparatus consists of a vertical, cylindrical vessel with a series of baffles placed inside, which help create an increased surface area for gas to be absorbed. The absorption column apparatus can be used to study the effect of different parameters, such as temperature and pressure, on the efficiency of the absorption process and to develop more efficient systems for industrial processes. Absorption column apparatus can also be used to simulate a wide variety of industrial processes, from gas storage and recovery processes to chemical reactors. Additionally, it can be used to study the effects of impurities on the absorption process, allowing for the development of more efficient separation technologies. The results of these studies help researchers to design new materials, processes, and systems that can be applied to a wide range of industrial applications.

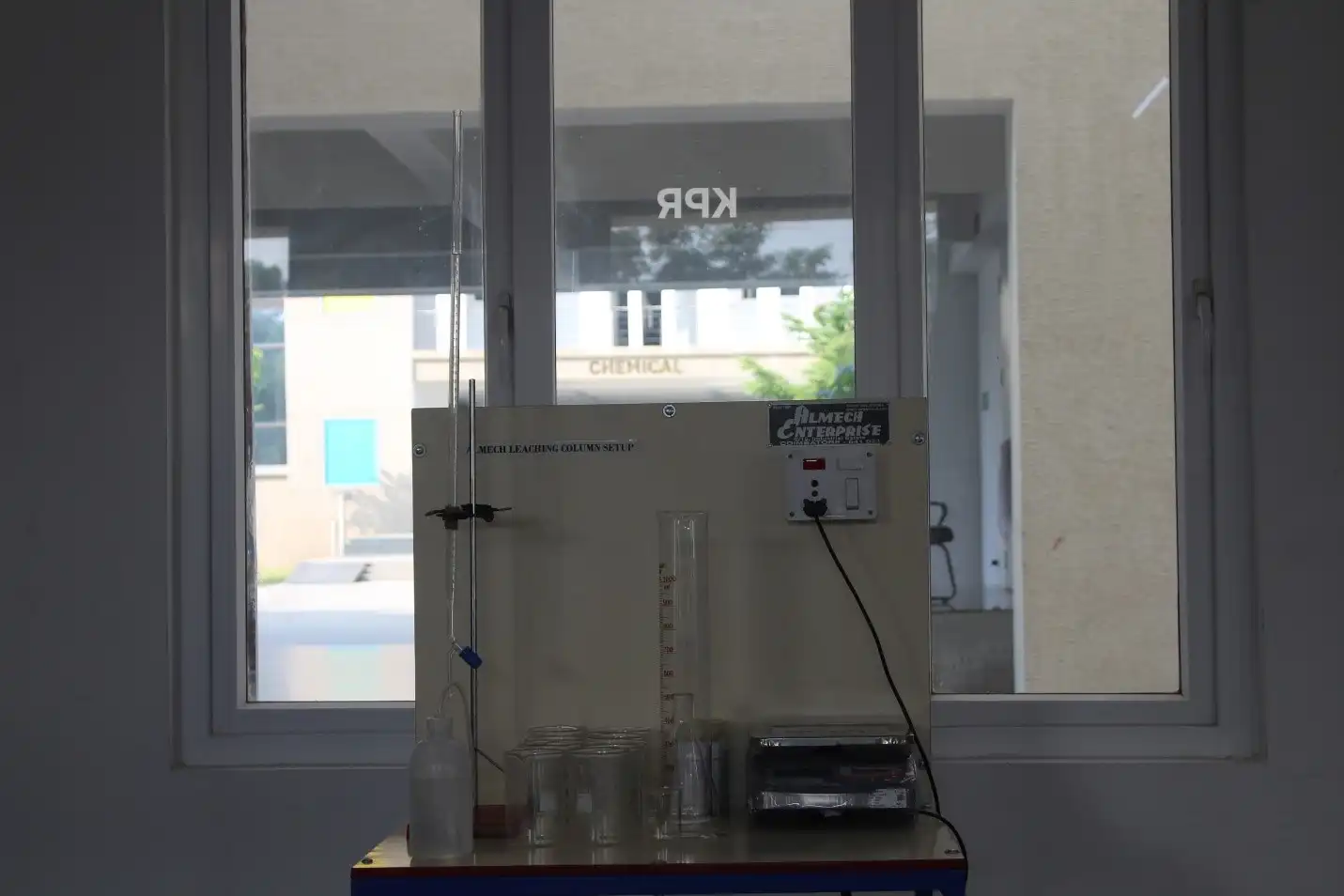

Leaching is a process used in the mass transfer laboratory to isolate certain dissolved compounds from one another. It involves the use of a leaching column, which consists of a series of stacked trays containing the material to be leached. As the liquid passes through the column, the desired compounds are removed from the mixture and collected in the lower trays. Leaching helps researchers gain a better understanding of the physical and chemical processes involved in separating and refining materials and can be used to develop more efficient separation technologies. Leaching column apparatus can be used to study the effects of various parameters, such as temperature and pressure, on the efficiency of the leaching process. Leaching column apparatus can also be used to study the effects of impurities on the leaching process and to develop more efficient purification technologies. Additionally, it can be used to simulate a wide variety of industrial processes involving separation and refinement, such as those used in petroleum refining, recycling of valuable metals, and water treatment.

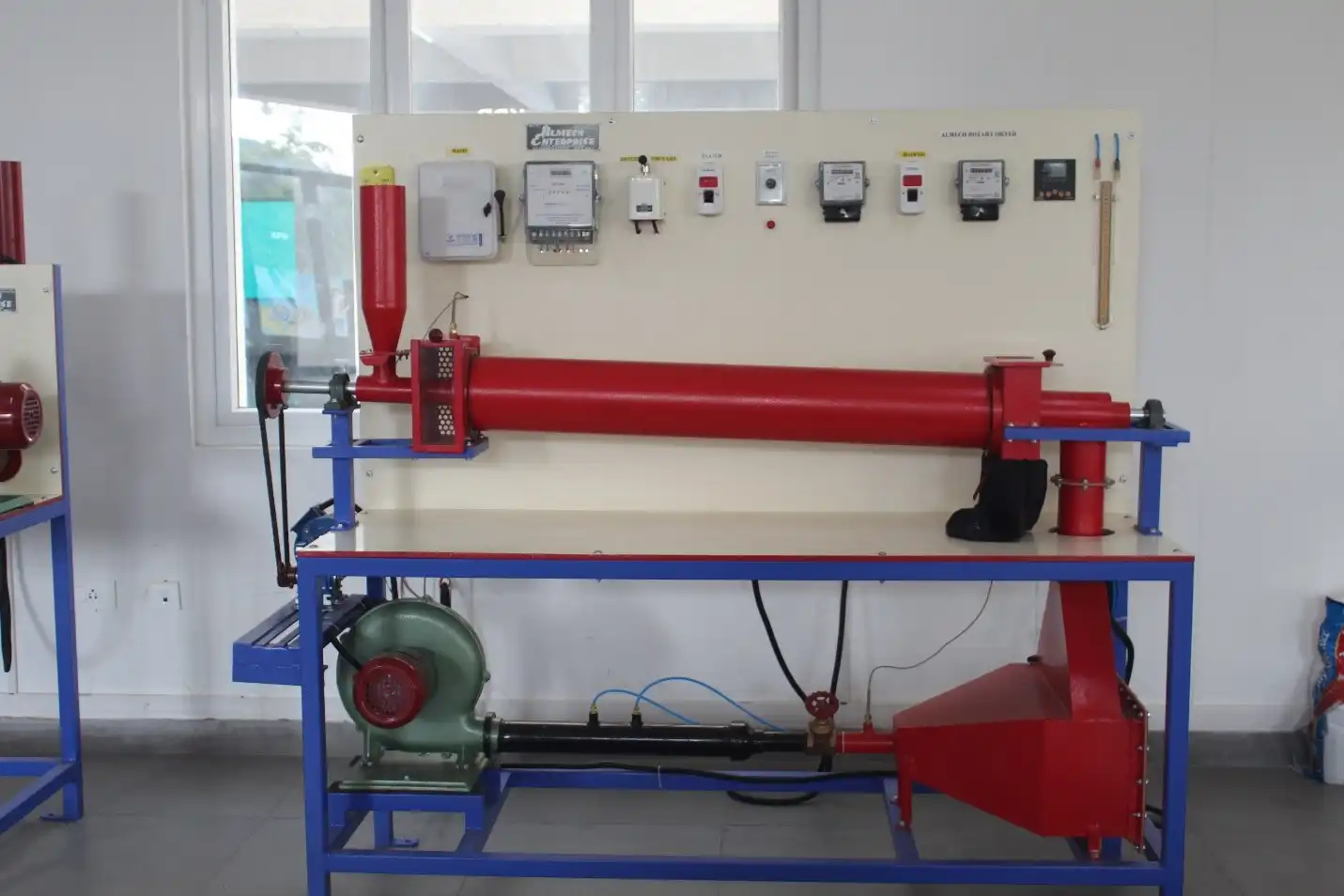

A rotary dryer apparatus is a type of mass transfer device used in laboratories to study drying processes. It consists of a rotating drum, typically filled with material to be dried, and heated air is passed through the drum, evaporating the moisture from the material. The resulting vapor is collected and analyzed to gain a better understanding of the drying process. This type of apparatus helps mass transfer researchers gain a better understanding of evaporation and dehydration processes, which can be applied to the development of more efficient separations, reactors, and other advanced systems.

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidity affects rate of evaporation of water. When the molecules of the liquid collide, they transfer energy to each other based on how they collide. When a molecule near the surface absorbs enough energy to overcome the vapor pressure, it will escape and enter the surrounding air as a gas. When evaporation occurs, the energy removed from the vaporized liquid will reduce the temperature of the liquid, resulting in evaporative cooling. Surface Evaporation apparatus consists of a shallow pool of liquid with an exposed surface area on top. As the liquid is heated, a thin film of vapor forms on the surface that can be collected and analyzed to gain a better understanding of the evaporation process. This type of apparatus can be used to study the effect of various parameters, such as temperature and pressure on the rate of evaporation.

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. Adsorption is a surface phenomenon and does not penetrate through the surface to the bulk of the adsorbent , while absorption involves the whole volume of the material, although adsorption does often precede absorption. It involves the use of an adsorption column, which consists of a series of stacked trays containing material that has adsorbent properties. As the liquid passes through the column, the desired compounds are adsorbed onto the material in the column, resulting in a purified solution. The adsorption column apparatus is most commonly used for the treatment of waste water from various sources.