The Mechanical Operations Laboratory in Chemical Engineering is a state-of-the-art facility that allows students to explore the fundamentals of mechanical operations. This laboratory provides an interactive environment where students can gain firsthand experience in the application of mechanical operations to chemical engineering. The laboratory is equipped with several pieces of equipment, including Cyclone separator, Ball Mill, Jawcrusher, Elutriator, Plate and frame filter press, and a variety of other pieces of machinery.

Students learn to use the equipment to simulate processes and improve their understanding of the principles behind these operations. The laboratory also provides students with the opportunity to work with a variety of materials, such as solids, liquids, and gases. Through the use of the equipment, students are able to study the effects of these parameters on the physical and chemical behavior of materials.

In addition, the laboratory also provides students with the opportunity to practice operating the equipment and learn about the safety precautions that must be taken when using the equipment.

Crushers are slow speed machines for coarse reduction of large quantities of solid. Jaw crusher operates by compression and can break lumps of hard material as in the primary and secondary reduction of rocks and ores.

The jaw crusher consisting of two crushing surfaces called jaws, one fixed and one movable. Feed is admitted between the two jaws to form a ‘v’ type open. The fixed jaw is nearly vertical and does not move. The other jaw is called the swinging jaw (or) anvil jaw reciprocates on the horizontal plane. It makes an angle of 20 0 -30 0 with the fixed jaw.

It was drawn by an eccentric or motor, so that it applies great compression force to the feed caught between the two jaws. Large lumps are broken and dropped into the narrow space below and are recrushed.

A crusher cannot be expected to perform satisfactorily unless,

Sedimentation is a phase separation process in which the solid particles settle out from the slurry under the action of gravity force. In a sedimentor a suspension or slurry is separated into a supernatant clear liquid and a thick sludge. The process is termed thickening if the concentrated sludge is the main desired product and it is called clarification if the recovery of the clear liquid is the prime requirement.

When the particles are at sufficient distance from the boundaries of the container and from other particles, so that it falls without being affected, then it is called “free settling”. Slurry taken in a graduated cylinder can be observed to study the hindered settling phenomenon of aggregated flocs of fine particles.

The well mixed slurry in the cylinder up to a given height will develop a clear liquid zone at the top having a clear boundary with the slurry below it. This is because the hindered settling of fine particles as flocs displaces the liquid upward to form a clear liquid zone. The continuous down-ward movement of solid flocs and up-ward movement of the displaced liquid make the interface boundary to descend down continuously.

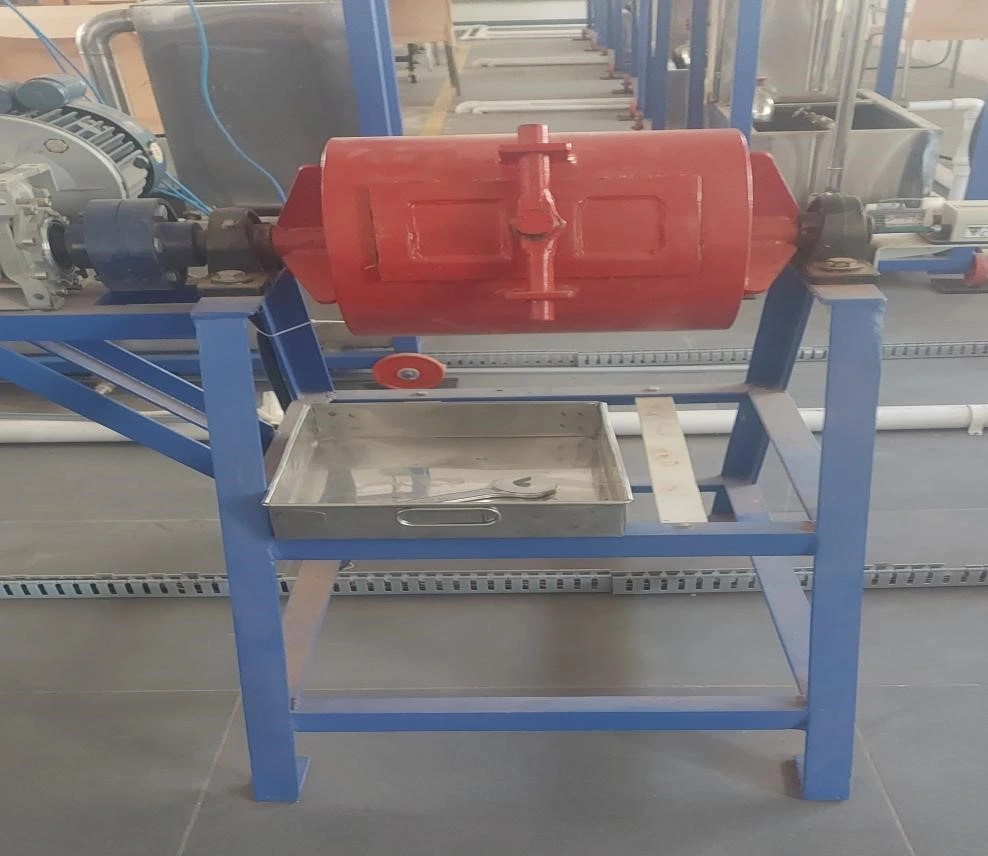

The ball mill is classified as an intermediate and fine grinder where the action of the grinder is based on impact and attrition.

The ball mill consists of a cylindrical shell about a horizontal axis and filled to about half of its volume with a solid grinding medium. The shell is usually lined with high carbon steel or rubber. The grinding medium is metal balls that range from 1 to 5 inch diameter.

When the mill is rotated the balls are picked by the mill wall and carried nearly to the top where they break contact with the wall and fall to the bottom to be picked up again. Centrifugal force keeps the ball in contact with the wall and with each other during the upward movement.

At low speeds of rotation the balls simply roll over one another and little crushing action is obtained. At slightly higher speeds, they are projected short distances across the mill, and at still higher speeds balls are thrown greater distance and considerable wear of the lining of the mill takes place.

At very high speeds the balls are carried right round in contact with the sides of the mill and little grinding takes place, the mill is then said to be centrifuging. The speed of the mill at which centrifuging occurs is called Critical speed. For efficient operation of the mill, it should always be run at a speed less than the critical speed and hence determination of critical mill speed becomes important.

The mill may be operated continuously or batch wise. In batch operation measured quantity of solid was ground in the mill for several hours, when the mill is stopped the product discharges through the opening in the shell. In continuous mill the solids flow steadily with feed entering at one end and the product discharges through the other end of the shell.

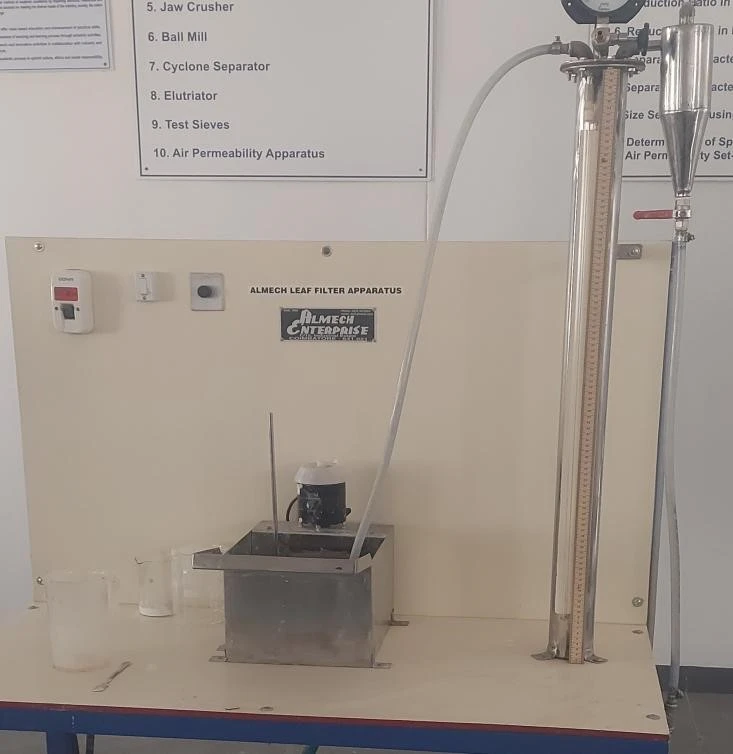

The unit consists of a slurry tank fitted with a variable speed impeller. The speed of the impeller may be adjusted by a regulator. The leaf filter assembly includes filter cloth. From the filter assembly a tube connects the filtrate tank provided with level gauge.

Recessed-plate filter presses are used to remove water from liquid wastewater residuals and produce a non-liquid material referred to as “cake”. Recessed-plate filter presses are among the oldest types of dewatering devices and can produce the highest cake solids concentration of any mechanical dewatering equipment

Cyclone separator was widely used for dust removal in industry. In the cyclone separator the separating dust is subjected to tangential and radial component of centrifugal force.

Separating factor was defined as S = v2/r magnitude of centrifugal force compared to gravitational force. Thus cyclone separators are efficient in removal of smaller particles than the gravitational settling chamber.

The gas particles on entering the cyclone receive a rotating motion because the entrance was tangential at the top of the cylindrical portion. The vortex formed from the centrifugal force forces the particles to move rapidly. The gas flow reverses to form an inner vortex which leaves through the outlet pipe provided at the top axially

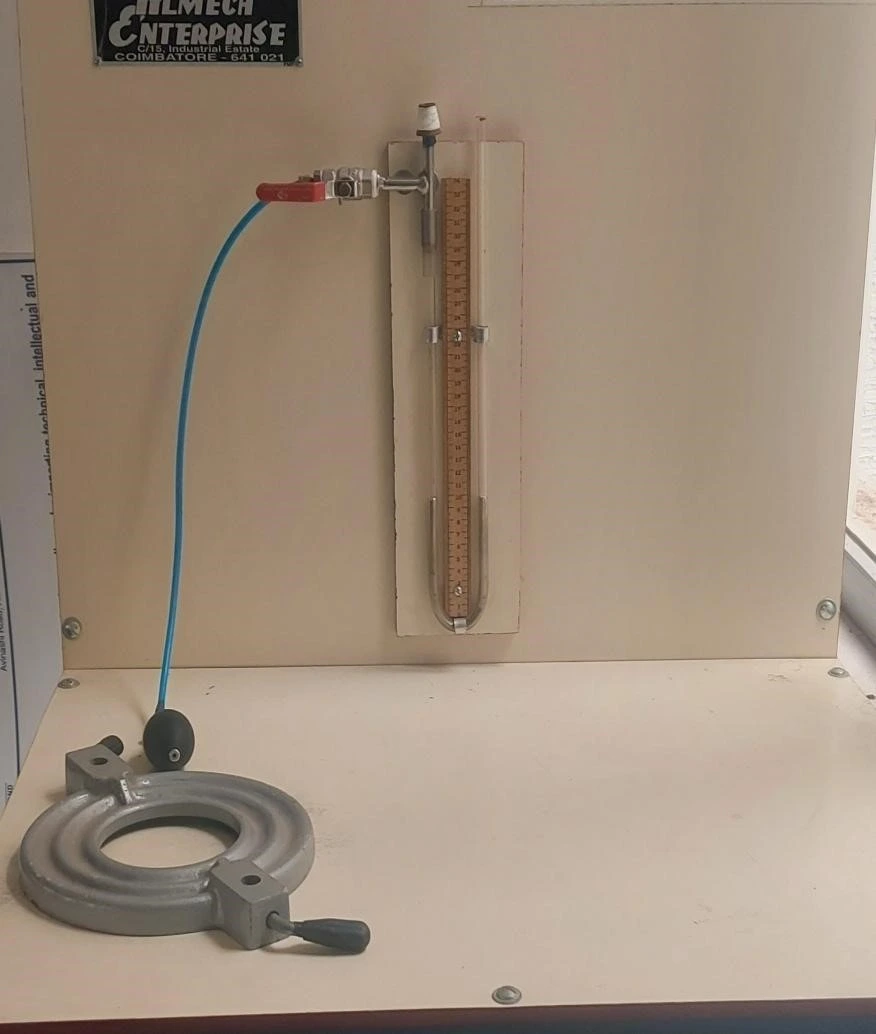

In the simplest type of vertical gravity elutriator the fluid tends to carry the particles up through a column, but this motion is opposed by gravity, so that only particles smaller than a certain critical size are swept out. Since the velocity profile across the moving fluid is parabolic, larger particles can be supported in the middle of the column than at the sides.

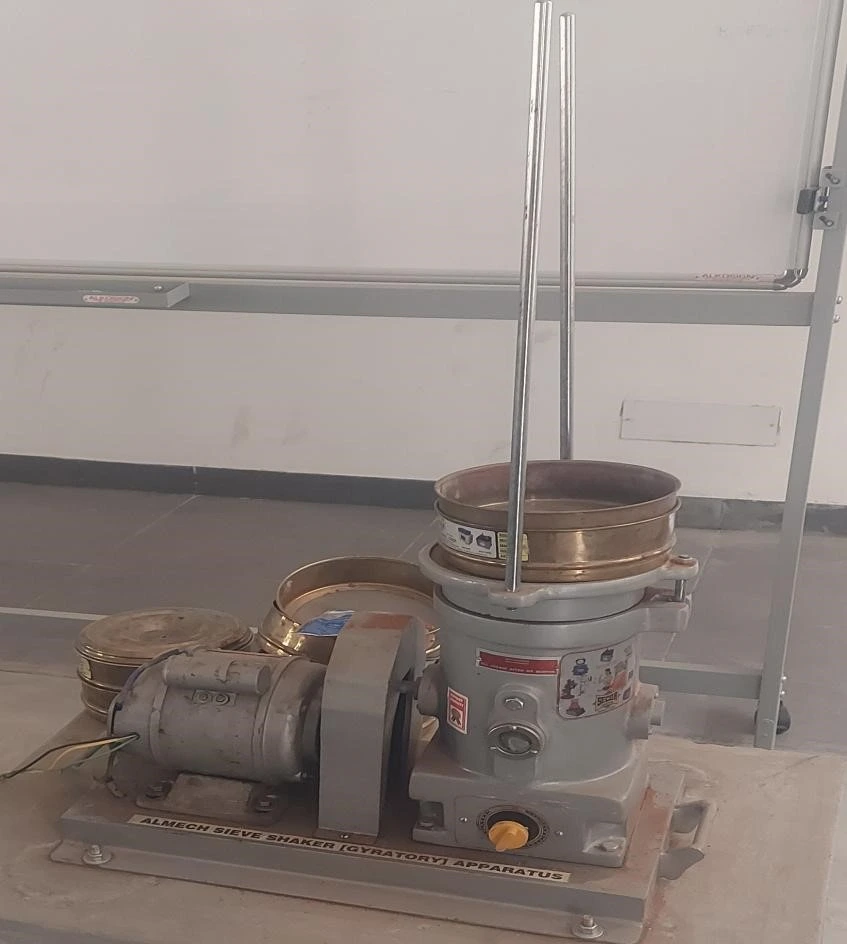

Screening is a method of separating particles according to the size alone. In industrial screening solids are dropped on or throw against a screening surface. Materials passed through a series of screens of different size are separated into size fraction (i.e) fraction in which both the maximum and minimum particle sizes are known.

Screening is occasionally dry. Industrial screens are made from woven wire, silk or plastic cloth, metal bars, perforated or slotted plate or wires, that are wedge shaped in cross section.

The vibrating screen set consists of many screens arranged one alone, the screen having large opening is at top and the other screens are placed under this in order of decreasing open size. There are usually discharge ducts to permit removal of several fractions.

Screens that are rapidly vibrated with small amplitude and are less likely to blind than gyrating screens. The vibrations may be generated mechanically or electrically. Mechanical vibrations are usually transmitted from high speed eccentrics to the casing of the unit and from there to steeply inclined screens.