This scientific laboratory was established since the establishment of the Department of Electrical Engineering and is being updated now and then. The laboratory contains all the AC machines and Transformers for carrying experiments for various engineering branches. Experiments are carried out on three-phase and single-phase induction machines, as well as experiments on synchronous motors and generators. In addition, experiments on special machines are also conducted. The lab is used for student’s project and product development purposes.

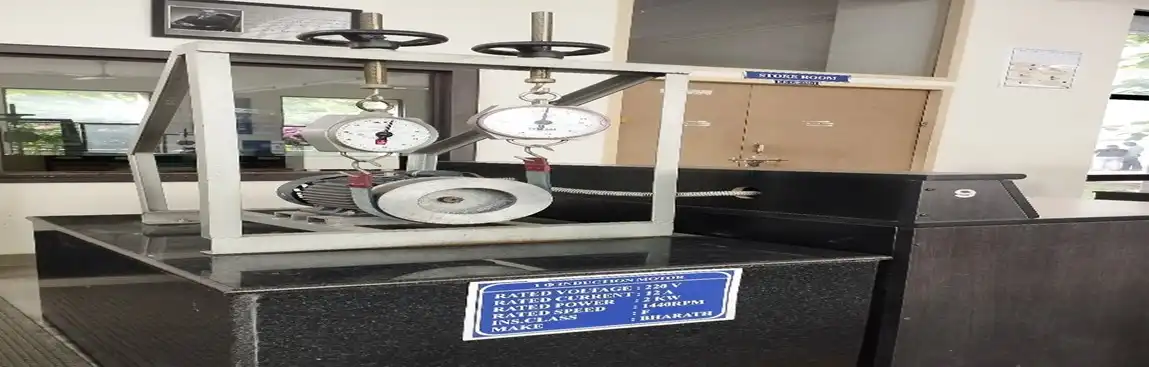

Single-phase induction motors are the most familiar electric motors because these are commonly used in domestic and commercial appliances like fans, pumps, washing machines, air conditioners, refrigerators, etc. Although single-phase induction motors are relatively less efficient than three-phase induction motors, but they are extensively used as the substitute for three-phase induction motors in low power applications. The stator of a single-phase induction motor carries a single-phase winding, whereas the rotor has the squirrel-cage construction.

Single-phase salient pole alternators are less common compared to their three-phase counterparts. Similar to their three-phase counterparts, these alternators have a rotor with protruding poles, which distinguish them from non-salient pole designs. The stator typically contains a single-phase winding arrangement. Single-phase salient pole alternators operate similarly to their three-phase counterparts but are designed specifically for single-phase power generation.

A 3 phase squirrel cage induction motor is a type of three phase induction motor which functions based on the principle of electromagnetism. It is called a ‘squirrel cage’ motor because the rotor inside of it - known as a ‘squirrel cage rotor’ - looks like a squirrel cage. One big advantage of a squirrel cage motor is how easily you can change its speed-torque characteristics. This can be done by simply adjusting the shape of the bars in the rotor.

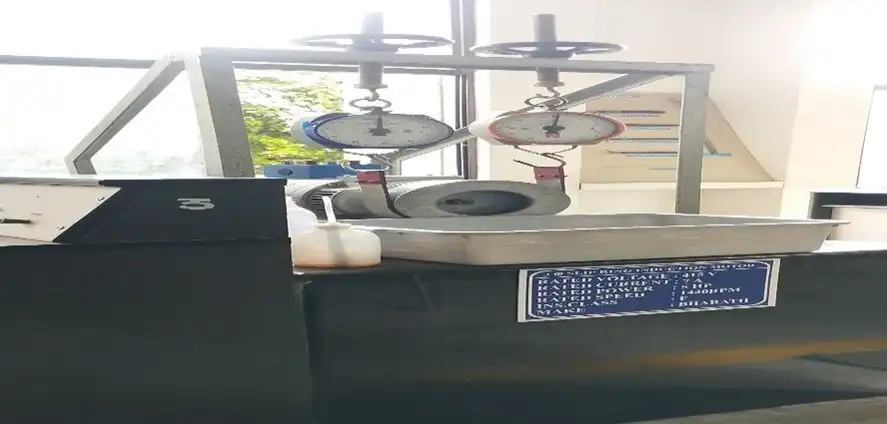

The three-phase slip ring (or wound rotor) induction motor aligns closely with that of a standard three-phase induction motor. However, slip ring induction motors possess additional features and capabilities due to the presence of slip rings and external resistance connected to the rotor windings. Three-phase motors with slip ring rotors are generally characterized by high torques upon starting, a low starting current, and a smooth start at high load.

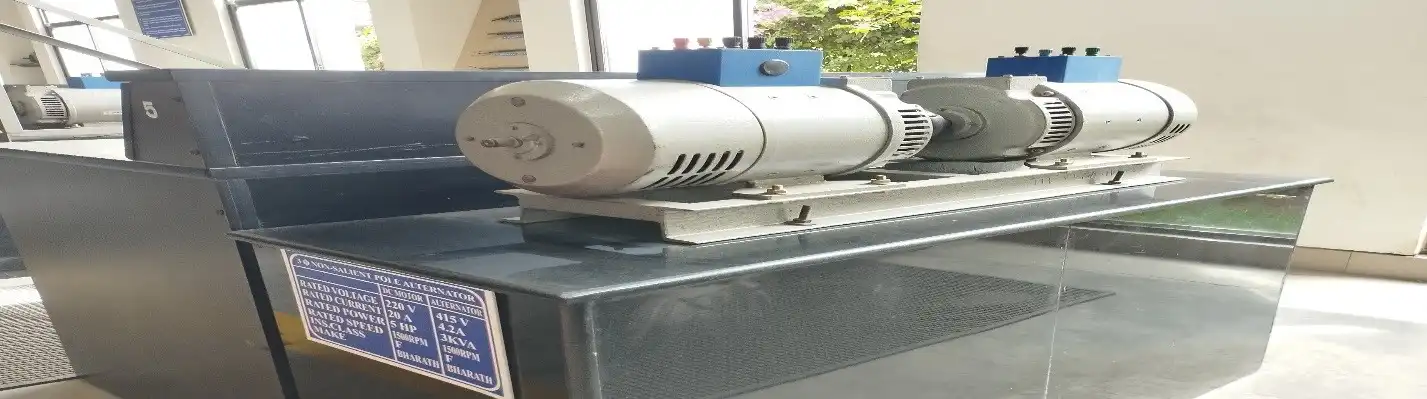

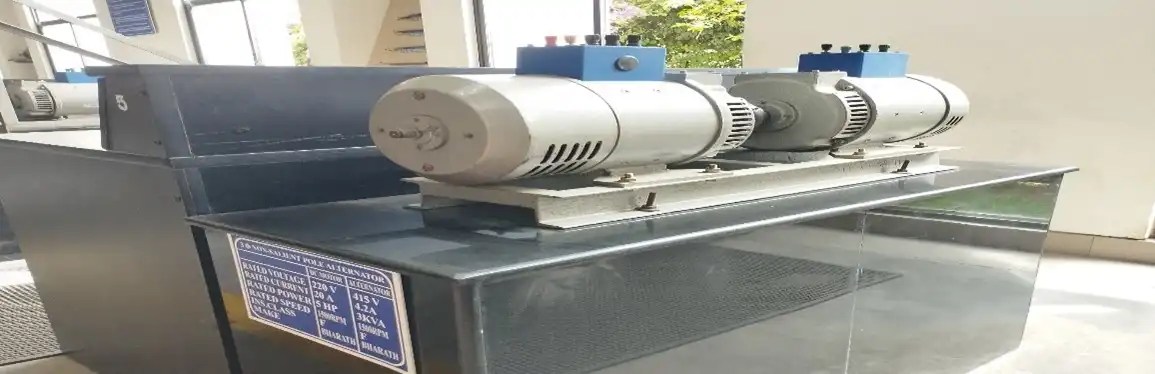

The synchronous machines are the most extensively used electrical machines in power system applications like power generator, power factor correction, driving constant speed mechanical load, etc. The synchronous machine which converts mechanical energy into alternating current electricity is called a synchronous generator or alternator. While the synchronous machine which converts alternating current electricity into mechanical energy is called a synchronous motor.

In salient pole alternator the field windings on the rotor have protruding poles, unlike the cylindrical rotor of a non-salient pole alternator. Salient pole alternators are commonly used in applications where the requirement is for low to medium speed and high-power generation. They are suitable for power generation in hydroelectric plants, diesel generators, or other systems where adjustable speed operation might be required.

A non-salient pole alternator has a rotor with a cylindrical shape, where the field windings are distributed uniformly around the rotor's circumference. Non-salient pole alternators are commonly used in applications where higher speeds and lower power generation are required. A three-phase non-salient pole alternator is an AC generator with a cylindrical rotor design, offering advantages in higher speed applications, mechanical strength, and balance, and finding application in power generation setups requiring higher speeds and lower power outputs.

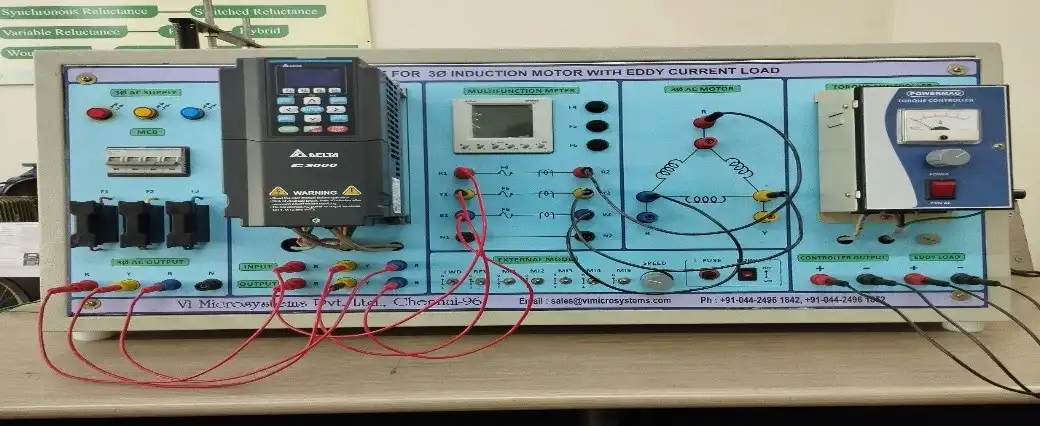

Eddy current loading in a three-phase induction motor occurs when the rotor experiences a form of power loss due to the presence of eddy currents induced in the rotor's conductive materials. When the rotor of a three-phase induction motor is subjected to a changing magnetic field, eddy currents are induced in the rotor's conductive parts (usually made of materials like aluminium or copper). The consequence of these eddy currents is the generation of heat within the rotor, which results in power losses and reduces the motor's efficiency. This effect is more prominent in high-speed induction motors and can limit their maximum speed due to the increased heat generated.