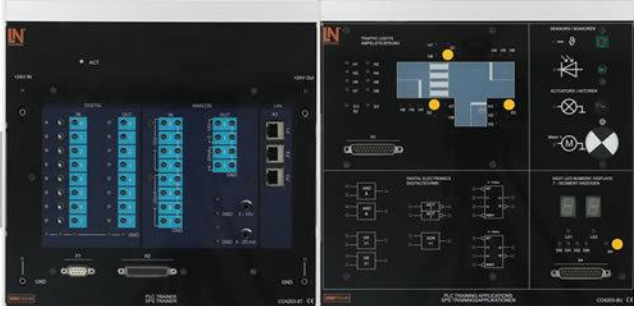

KPRIET Robotics and Automation Centre of Excellence is a state-of-the-art robotics and automation centre. It has been set up in the year 2022 with collaboration of Lucus Nuelle, Germany, a focus of strengthening smart Manufacturing, Industry 4.0 technology training and improving educational systems. A faculty team of has been taken training on Robotics and Automation by the LN Trainer from Germany.

To further improve the diversity and quality of training, an e-yantra embedded systems and robotics lab has been set up with the collaboration of E-Yantra Lab, IIT Bombay in the year 2021. In this CoE students get opportunity work on Firebird V and Spark Robots.